Why Are Some Types of PCBs More Expensive?

- by admin

- Posted on May 13, 2024

Types of PCBs More Expensive

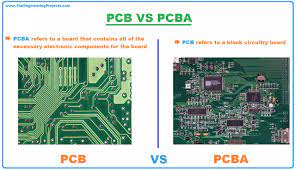

The cost of a PCB can vary depending on multiple factors, including the manufacturer, board size and complexity. More intricate designs typically require more time, materials and specialized tools to produce, which can increase the overall cost of the project. Additionally, some projects may require special certifications that are costly to maintain.

The number and type of layers in a circuit board can also influence its price. For example, the use of thicker copper foil can significantly increase production costs. This is because it requires more prepreg to fill gaps between the copper layers, which is a time-consuming process. Additionally, the thickness of a hole can also have a significant impact on the final cost of a PCB. The more challenging the hole design, the more difficult it is to drill through the layers.

Another factor that influences the cost of a pcba circuit board is the type of material used for each layer. A common material for a PCB is FR-4, which has a base copper weight of 1 ounce per square foot. However, a more dense metalization (such as 10 um or 18 um) can also increase production costs because it takes longer to laminate and press.

In addition to the type of material, a PCB’s copper thickness can have a significant impact on its price. A thinner copper foil can be more affordable than a thicker one, but it will have less current carrying capacity and be more difficult to work with. Thicker copper foils are also more expensive to buy and to transport, which can add to the overall cost of a circuit board.

Why Are Some Types of PCBs More Expensive?

Other factors that can increase a PCB’s price include the type of solder mask, legend and carbon print used to finish the board. These additional steps can make a PCB more durable, but they can also require more labor and specialized equipment. Additionally, special features on a PCB can require more specialized skills to create, which can also lead to higher production costs.

Surface mount PCBs use smaller leads to connect components, rather than traditional wires, which can be more space-efficient and cost-effective. They can be used to build a wide range of electronic devices, from simple LED lighting and power supplies to sophisticated industrial controls, automotive dashboards, vending machines and more. This type of PCB is usually more expensive than a through-hole circuit board because of the extra materials and production steps involved. However, it is more affordable than a flexible or rigid-flex PCB.

After the PCB is clean and free of any excess copper, it can be plated with tin to help guard against future corrosion. The tin plating is also useful for increasing the conductivity of the outer layer. This will allow the PCBA to perform as it should, and it will make it easier to solder components onto the surface.

Types of PCBs More Expensive The cost of a PCB can vary depending on multiple factors, including the manufacturer, board size and complexity. More intricate designs typically require more time, materials and specialized tools to produce, which can increase the overall cost of the project. Additionally, some projects may require special certifications that are costly…