What role do electronic PCB boards play in consumer electronics

- by admin

- Posted on May 3, 2024

electronic PCB boards play in consumer electronics

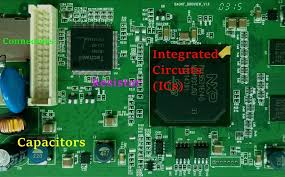

A circuit board connects all the components in an electronic device and provides a solid, reliable platform for their operation. The board contains conductive pathways made of copper, which transfer electrical signals from one component to another. This technology powers everything from mobile phones to heart rate monitors to rockets. To make a PCB, insulating material called a substrate is laminated to a conductive layer made of copper foil. A chemical etching process separates the copper into different layers. Each layer is etched to include pads for connections, traces that act as wires fixed in place, and vias that pass connections between the various layers of the PCB.

The design of a PCB can be done manually, but it is typically automated for large-scale production. The process starts with front-end engineering, where the functionality of the electronic circuit is defined. ECAD software is used to translate simple circuit diagrams into computer drawings that define the electrical connections between components and signals. These drawings are then analyzed with SPICE simulation tools to predict performance and check for errors before they are physically manufactured.

When a electronic pcb board is ready for production, the next step is to place all the individual parts onto the circuit board in their correct positions. This can be done by hand for prototyping and small-scale production, but is usually automated using a machine known as a pick-and-place machine. The machine uses a robotic arm to select and place the components onto the boards, connecting their leads to the corresponding conductive pathways on the board. The components are held in place by a small amount of solder paste, which is applied to the pads on the surface of the board before the component placement.

What role do electronic PCB boards play in consumer electronics

Some of the key elements on a circuit board are capacitors, diodes, resistors, and sensors. The capacitors provide a source of power to the circuit board, holding an electric charge and releasing it when needed. Diodes prevent current from flowing in the wrong direction and help regulate the flow of current within the circuit. The sensors detect input from the physical environment, such as vibration or motion, and respond by generating a corresponding signal on the PCB.

Once all the components are placed on the circuit board, the PCB must be assembled and soldered together. This can be done by hand for smaller-scale production and prototyping, but is typically automated for larger-scale manufacturing. A robot places each part into its correct position on the circuit board, attaching it to the appropriate traces and pads, using a small amount of solder paste.

A legend printed on the PCB (also referred to as silk screening or silk) contains information useful in assembling, testing, servicing, and using it. This information can include component designs and designations, switch settings, test points, or other indicators. The legend can be printed on the substrate or a separate piece of paper, and is either silkscreen printed or digitally reproduced. The digital reproduction is becoming increasingly popular as it can be more accurate and faster than the traditional method of silkscreen printing.

electronic PCB boards play in consumer electronics A circuit board connects all the components in an electronic device and provides a solid, reliable platform for their operation. The board contains conductive pathways made of copper, which transfer electrical signals from one component to another. This technology powers everything from mobile phones to heart rate monitors…