What advancements are being made in the technology of printed circuit board assembly?

- by admin

- Posted on May 14, 2024

technology of printed circuit board assembly

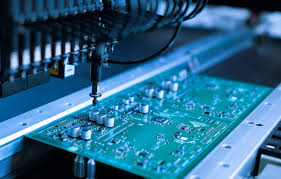

Advancements in printed circuit board assembly (PCBA) technology are driving innovation and reshaping the electronics manufacturing industry. As demand for smaller, more powerful, and energy-efficient electronic devices continues to grow, researchers and engineers are exploring new materials, processes, and techniques to enhance the performance, reliability, and sustainability of PCBAs.

One notable area of advancement in printed circuit board assembly technology is the development of miniaturized components and advanced packaging techniques. With the rise of Internet of Things (IoT) devices, wearable technology, and mobile devices, there is a growing need for PCBAs with smaller form factors and higher component densities. Manufacturers are leveraging technologies such as micro-electromechanical systems (MEMS), wafer-level packaging (WLP), and system-in-package (SiP) to achieve greater integration and functionality in compact PCB designs.

Another significant advancement in PCBA technology is the adoption of additive manufacturing, also known as 3D printing, for producing PCBs. Additive manufacturing enables the rapid prototyping and customization of PCB designs with complex geometries and features. By layering conductive and dielectric materials, manufacturers can create PCBAs with embedded components, optimized heat dissipation, and reduced weight. This approach not only accelerates the product development cycle but also offers new possibilities for design innovation and customization.

What advancements are being made in the technology of printed circuit board assembly?

Furthermore, advancements in surface-mount technology (SMT) and reflow soldering techniques are driving improvements in PCBA assembly processes. Miniaturization and automation of SMT equipment enable higher throughput, precision placement of components, and tighter control over soldering processes. Additionally, the introduction of lead-free solder alloys and environmentally friendly fluxes addresses concerns about the impact of traditional soldering materials on human health and the environment.

In recent years, there has been a growing emphasis on sustainability and environmental responsibility in PCBA manufacturing. As a result, researchers and manufacturers are exploring eco-friendly materials and processes to reduce the environmental footprint of PCB production. This includes the use of recyclable or biodegradable substrates, lead-free soldering alternatives, and energy-efficient manufacturing techniques. By adopting sustainable practices, manufacturers can minimize waste, conserve resources, and meet the increasing demand for environmentally conscious products.

Moreover, advancements in inspection and testing technologies are enhancing the quality and reliability of PCBAs. Automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT) systems enable thorough analysis of PCBAs for defects, solder joint integrity, and electrical performance. Real-time monitoring and feedback mechanisms facilitate rapid identification and resolution of issues during the production process, ensuring that only high-quality PCBAs reach the end-user.

The integration of artificial intelligence (AI) and machine learning algorithms is also revolutionizing PCBA manufacturing by optimizing process control, predictive maintenance, and quality assurance. AI-driven analytics enable proactive decision-making and continuous improvement, leading to higher yields, lower defect rates, and greater overall efficiency in PCB production facilities.

In conclusion, advancements in printed circuit board assembly (PCBA) technology are driving innovation and shaping the future of electronics manufacturing. From miniaturized components and additive manufacturing to sustainable practices and AI-driven optimization, these advancements are enabling the development of smaller, more powerful, and environmentally friendly electronic devices. By embracing these technological innovations, manufacturers can stay competitive in a rapidly evolving industry and meet the demands of today’s increasingly interconnected and digitized world.

technology of printed circuit board assembly Advancements in printed circuit board assembly (PCBA) technology are driving innovation and reshaping the electronics manufacturing industry. As demand for smaller, more powerful, and energy-efficient electronic devices continues to grow, researchers and engineers are exploring new materials, processes, and techniques to enhance the performance, reliability, and sustainability of PCBAs.…