How to Handle Warped PCBs During Rigid Flex Processing

- by admin

- Posted on April 27, 2024

Handle Warped PCBs During Rigid Flex Processing

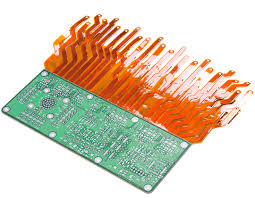

PCB warping refers to a change in the shape of a circuit board that was not intended. It can occur during a soldering process, and it can affect the integrity of the traces and components on the PCB. Rigid-flex circuit boards are often used in products such as laptop computers, smartphones, and wearable devices.

To avoid the need to replace a warped PCB, it is important to understand what causes it in the first place. In addition to the effects of temperature and moisture, there are other factors that can contribute to PCB warpage. For instance, if the thickness of a copper layer is too small, it can cause warping when it is bent. This can lead to poor solder linkage, which can result in shorts.

Another potential cause of warpage is the use of acrylic adhesives in rigid-flex PCB coverlayers or bondplies. These materials have a high Z-axis coefficient of thermal expansion and can stress the plated through holes (PTH) in flexible sections of the circuit board. This can impact signal integrity and electromagnetic interference (EMI).

While it may seem counterintuitive, if a circuit board has too little copper, it can also be warped during rigid flex processing. This is because the excess copper will absorb heat more readily than the PCB laminate and may cause it to flex. This can also lead to the formation of twisted sections and fractured traces.

How to Handle Warped PCBs During Rigid Flex Processing

A third factor that can cause PCB warpage is excessive bending or tight bend radiuses. In order to avoid warping, the bending radius of the flex section should be less than the bend radius of the rigid section of the circuit board. The flex section should also be bent at the center of the circuit board, rather than at a corner.

Moreover, if the circuit board is exposed to moisture during the manufacturing or assembly process, it can lead to PCB warping. The moisture can seep into the voids between the metallization and the substrate, causing them to expand. This can cause the corners of a BGA package to curve upward, which can lead to bridges and open circuits.

It is important to address a PCB warpage problem as soon as possible. Otherwise, it can damage the components and traces during operation and assembly. It can also affect the reliability of the device. In addition, a warped PCB is more likely to crack under mechanical stress, which can damage the circuit board and lead to fatigue failure in solder joints and traces.

It is best to contact the manufacturer of a PCB that is prone to warping before trying to fix it. Doing this will allow the manufacturer to identify the cause of the problem and correct it. It is not recommended to try to fix a warped circuit board yourself by heating and pressing it, which could make the problem worse or even delaminate the board material. This is because the heating and pressing method would essentially be mimicking the lamination process that the PCB was built with.

Handle Warped PCBs During Rigid Flex Processing PCB warping refers to a change in the shape of a circuit board that was not intended. It can occur during a soldering process, and it can affect the integrity of the traces and components on the PCB. Rigid-flex circuit boards are often used in products such as…